Isimiso sokukhetha isisetshenziswa

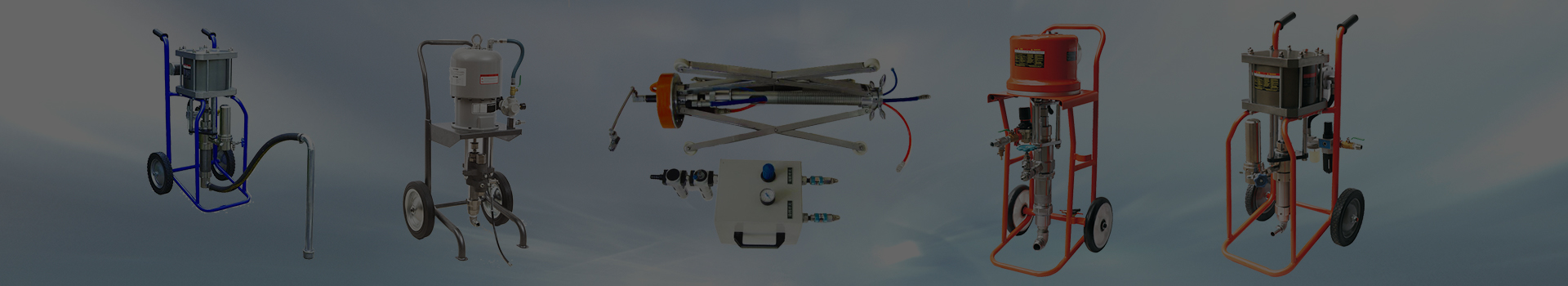

Kunezinhlobo eziningi zemishini yokufafaza engenawo umoya, ezokhethwa ngokwalezi zinto ezintathu ezilandelayo.

(1) Ukukhethwa ngokwezici zokumboza: okokuqala, cabangela i-viscosity ye-coating, bese ukhetha imishini enezinga eliphezulu lokucindezela noma uhlelo lokushisa lokumboza nge-viscosity ephezulu kanye ne-atomization enzima.Imishini ekhethekile enemodeli ekhethekile izokhethwa ukuze kuhlanganiswe izingxenye ezimbili, ukugqoka okusekelwe emanzini, ukugqoka okucebile kwe-zinc nezinye izigqoko ezikhethekile.

(2) Khetha ngokuya ngesimo se-workpiece eboshwe kanye neqoqo lokukhiqiza: lesi yisici esiyinhloko sokukhetha imishini.Ngeqoqo elincane noma elincane lezinto zokusebenza eziboshiwe, ngokuvamile khetha imodeli ngenani elincane lokufafaza ngopende.Ngeqoqo elikhulu nelikhulu lezinto zokusebenza, njengemikhumbi, amabhuloho, izimoto, imigqa ezenzakalelayo eqhubekayo yokudweba, khetha imodeli enenani elikhulu lokufafaza ngopende.Ngokuvamile, umthamo wokufafaza upende<2L/min mncane, 2L/min – 10L/min uphakathi, futhi>10L/min mkhulu.

(3)Ngokomthombo wamandla okhona, imishini yokufafaza engenawo umoya ingakhethwa ngoba kunemithombo yomoya ecindezelwe ezindaweni zokusebenza ezijwayelekile zokufafaza.Uma ungekho umthombo womoya ocindezelwe kodwa ugesi kuphela, okokusebenza kagesi okufafaza okungenamoya kuzokhethwa.Uma kungekho mthombo womoya noma amandla, imishini yokufafaza engenamoya eshayelwa yinjini ingakhethwa

Izinzuzo zomshini wokufafaza ongenawo umoya onengcindezi ephezulu:

1. Ukusebenza kahle kakhulu kokufafaza.Isibhamu se-spray sifutha ngopende ngokuphelele.Ukugeleza kwesifutho kukhulu, futhi ukusebenza kahle kokwakhiwa cishe izikhathi ezi-3 kunomoya.Isibhamu ngasinye singafutha 3.5~5.5 ㎡/min.Umshini wokufafaza ongenawo umoya onengcindezi ephezulu kakhulu ungasebenzisa izibhamu ezifuthwayo ezifika kweziyi-12 ngesikhathi esisodwa.Ubukhulu be-nozzle ububanzi bungafinyelela ku-2mm, obufanele ukunamathisela okuhlukahlukene okugqinsiwe.

2. Ukuphindaphinda okuncane kopende.Upende olufuthwe umshini wokufafaza komoya uqukethe umoya ocindezelwe, ngakho uzophindeka lapho uthinta indawo engaphezulu yento ezogcotshwa, futhi inkungu kapende izondiza isuke.Inkungu kapende efuthwe ngokufafaza okungenamoya onengcindezi ephezulu ayinakho ukuphindeka ngenxa yokuthi awukho umoya ocindezelwe, onciphisa izinwele ezifuthwayo ezibangelwa ukundiza kwenkungu kapende, futhi ithuthukisa izinga lokusetshenziswa kopende kanye nekhwalithi yefilimu kapende.

3. Ingafuthwa ngopende we-viscosity ophezulu futhi ophansi.Njengoba ukuthuthwa nokufafazwa kwezingubo kwenziwa ngaphansi kwengcindezi ephezulu, ukugqoka okuphezulu kwe-viscosity kungafafazwa.Umshini wokufafaza ongenawo umoya onomfutho ophezulu ungasetshenziswa ngisho nokufafaza izimbotshana eziguquguqukayo noma izimbotshana ezinemicu.I-viscosity yokumboza yomshini wokufafaza ongenawo umoya onengcindezi ephezulu ingaba phezulu njenge-80 s.Ngenxa yokuthi i-coating ene-viscosity ephezulu ingafuthwa futhi okuqukethwe okuqinile kwe-coating kuphezulu, ukugqoka okufuthwe ngesikhathi esisodwa kukhulu kakhulu, ngakho-ke izikhathi zokufafaza zingancishiswa.

4. I-workpiece enesimo esiyinkimbinkimbi inokuguquguquka okuhle.Ngenxa yengcindezi ephezulu yomshini wokumboza ongenawo umoya, ungangena ezimbotsheni ezincane endaweni yokusebenza eyinkimbinkimbi kakhulu.Ngaphezu kwalokho, upende ngeke luhlanganiswe namafutha, amanzi, omagazini, njll emoyeni ocindezelwe ngesikhathi sokufafaza, ukuqeda ukukhubazeka kwefilimu yepende ebangelwa amanzi, amafutha, uthuli, njll emoyeni ocindezelweyo, ukuze upende omuhle. ifilimu ingakhiwa ngisho nasezikhaleni nasemakhoneni.

Ububi:

Ububanzi bamaconsi enkungu kapende omshini wokufafaza ongenawo umoya onomfutho ophezulu ngu-70~150 μ m.20~50 womshini wokufafaza emoyeni μ m.Izinga lefilimu yepende libi kakhulu kunelo lokufafaza emoyeni, elingafaneleki ukumbozwa kokuhlobisa kwengqimba encane.Ububanzi nokuphuma kwesifutho akukwazi ukulungiswa ngesikhathi sokusebenza, futhi umlomo wombhobho kufanele ushintshwe ukuze kuzuzwe injongo yokulungiswa.

Isikhathi sokuthumela: Dec-02-2022